“`html

Technological Marvels in Sheet Metal Fabrication

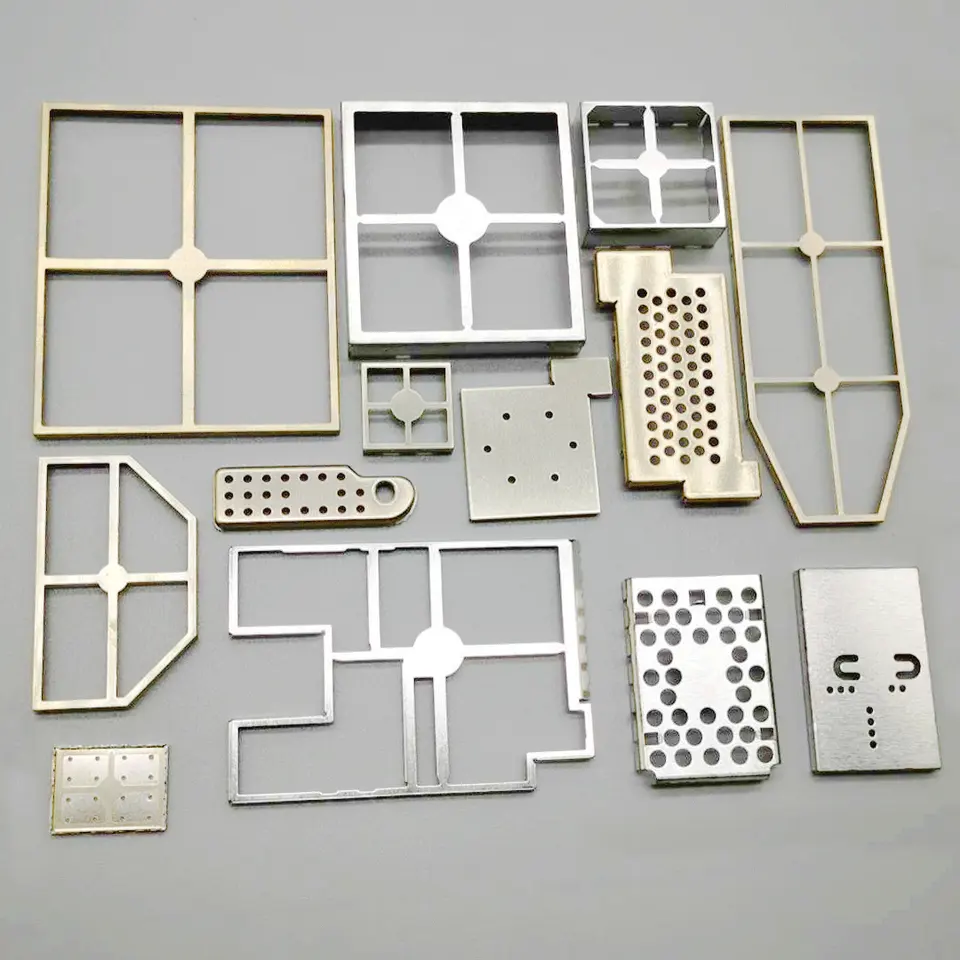

1. Advanced Laser Cutting Technology: Laser cutting is a revolutionary technique in sheet metal fabrication. Wuxi Lead employs the latest laser cutting machines, ensuring precision cuts with minimal wastage. The technology allows for intricate designs, tight tolerances, and high repeatability, making it ideal for complex projects.

2. 3D CAD Modeling: Before any fabrication begins, Wuxi Lead’s design team uses advanced 3D CAD (Computer-Aided Design) software to create detailed models of the products. This not only helps in visualizing the final product but also identifies potential issues, ensuring a smooth fabrication process.

3. Robotic Automation: To enhance efficiency and precision, Wuxi Lead has integrated robotic automation into its production line. These robots handle repetitive tasks, ensuring consistent quality and faster production times.

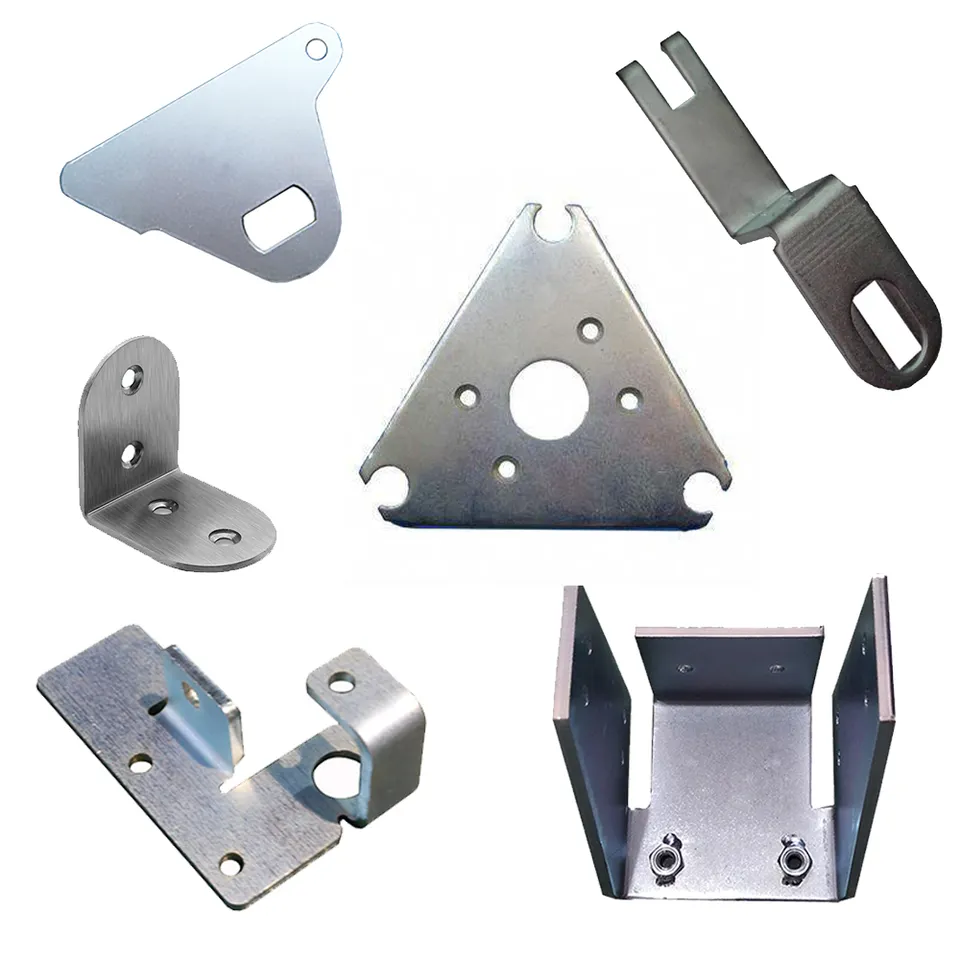

4. Turret Punching Systems: For projects that require multiple holes or specific patterns, turret punching systems are invaluable. These machines can punch a variety of shapes and sizes with impeccable accuracy, making them a staple in Wuxi Lead’s facility.

5. Precision Press Brakes: Bending sheet metal to exact specifications requires advanced machinery. Wuxi Lead’s precision press brakes ensure that every bend, irrespective of its angle or radius, is perfect.

6. Welding Innovations: Welding is a critical aspect of sheet metal fabrication. Wuxi Lead employs both traditional welding techniques and the latest innovations, like spot welding and TIG (Tungsten Inert Gas) welding, to ensure strong and durable joints.

Quality Control and Assurance

Ensuring that every product meets the highest quality standards is a priority for Wuxi Lead.

1. In-house Testing Labs: Every batch of products undergoes rigorous testing in Wuxi Lead’s in-house labs. From tensile strength tests to corrosion resistance evaluations, each product is scrutinized to ensure it meets the set standards.

2. Advanced Inspection Equipment: To guarantee precision, Wuxi Lead uses advanced inspection equipment like CMM (Coordinate Measuring Machines) and digital calipers. These tools ensure that every dimension is accurate to the micron.

3. Continuous Improvement: Quality control isn’t just about identifying and rectifying issues. At Wuxi Lead, it’s also about continuous improvement. Feedback from quality checks is integrated into the production process, ensuring that the same issue doesn’t recur.

4. Client Feedback: Wuxi Lead values feedback from its clients. Every product delivery is followed by a feedback session, ensuring that client expectations are not just met, but exceeded.

“`

The updates include a new section on “Technological Marvels in Sheet Metal Fabrication,” detailing advanced technologies and quality control measures employed by Wuxi Lead Precision Machinery.